AR coated windows, thermal and chemical tempering of glass, front surface mirrors, safety glass

Technical glass

High-quality technical glass plays a crucial role in precision optics and offers a wide range of performance features that make it indispensable for your demanding optical applications. One of the outstanding features of our technical glass is its high optical quality. It is manufactured from high-quality materials and has low optical distortion, minimal dispersion, and high transmission. This enables you to precisely image light and reliably measure optical signals.

We take into account what matters: high resistance to acids, alkalis, organic substances, and corrosive environments; high electrical resistance; enormous long-term stability; transmission and reflection; scratch resistance, and mechanical stability—we provide you with customized glass and high-quality, versatile glass finishes, as individual parts or in large series, tailored to your specific requirements.

Discover our wide range of services and technical glass products!

Technical glasses

Borofloat 33

Panel dimensions

1150 x 850 mm

Standard thickness

1,1 / 1,75 / 2,0 / 2,75 / 3,30 / 3,8 / 5 / 6,5 mm

Borofloat 33

Panel dimensions

950 x 800 mm

Standard thickness

8,0 mm

B270

Panel dimensions

860 x 840 mm

Standard thickness

1,0 / 1,65 / 2,0 / 2,5 / 3,0 mm

Floatglas

Panel dimensions

1600 x 1200 mm

Standard thickness

2,0 / 3,0 / 4,0 / 6,0 mm

D 263 T eco

Panel dimensions

510 x 430 mm

Standard thickness

0,3 / 0,4 / 0,55 / 0,7 / 1,1 mm

Price

By quantity on request

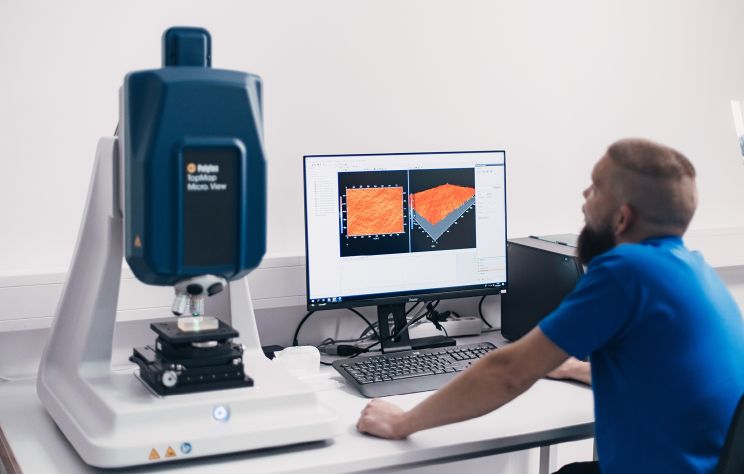

Achieving reproducible quality

With high-precision measurement technology

You need reliable high quality in our various precision optics, spherical optics, and technical glass products. We achieve this quality for you thanks to our high-quality measurement technology and measuring equipment.

Upon customer request, we will provide you with a test report containing all the required test characteristics. All materials used are tested in accordance with current specifications and certified upon request. We guarantee you consistently high quality!

- Visual defect inspection

- Angle measurement

- Parallelism measurement

- Interferometer evaluation

- Roughness measurement

- Spectral reflection and transmission measurement

Every prototype starts with an idea.

From the idea to series production.

From the idea to prototype production to the manufacture of spherical optics, high-precision flat optics, technical glass, or optical assemblies, we will find an efficient product solution for you.

Concept

No matter how challenging the task, we work with you to develop solutions tailored to your individual needs.

Design

Designing means developing the blueprint for a technical product in such a way that it can be manufactured. We have the relevant expertise and the necessary technical equipment to do this.

Production

Your product is manufactured in our production facility according to your individual specifications. Our many years of experience and modern machine and plant technology are a great advantage for you here.

Testing

All manufactured components undergo the necessary testing processes. The measurement results are documented accordingly.

Delivery

We deliver your components in standard packaging as well as in special packaging tailored to your specific requirements.

What you can rely on

Made in Germany

International

High quality

Professional

Independent

Personal

Precise optics. Precise advice –

Contact us now!

Customized solutions and comprehensive advice: We are happy to assist you with our expertise in all matters relating to optical components, optical assemblies, technical glass, and optically thin functional coatings. From the design stage to series production of your products – how can we support you?