Optical coatings for the most stringent requirements.

MICROS Optics develops and produces optical and optoelectronic functional coatings on all types of glasses, glass ceramics and crystals. Years of experience of our experts in the area of different coating variants and the use of latest design software enables us to find the most optimal solution for your application with dielectric and metallic coatings in the spectral range of UV (190 nm) to IR (>12 µm).

We offer you a comprehensive ion-assisted coating technology including the suitable measurement and testing technologies for optical components of almost any geometry.

Antireflection coatings (AR-coatings)

Antireflection coatings Examples of coatings curves

Antireflection coatings (AR-coatings)

|

Application

|

- Nearly all optical applications in industry and measurement technology require substrates with anti-reflective coatings.

- In this, the transmission of substrates is increased by reduced reflection.

- The coatings can be optimized for one or several wavelengths.

|

|

Types of coating

|

- Single-layers coatings (MgF2)

- V-coating for individual wavelengths

- Double-V and triple-V coatings for several wavelengths

- Broadband multilayer AR-coating

- Laser coatings

- Special coatings as per client’s requirements

|

|

Our competences

|

- Hard, scratch-resistant coatings; less absorption; low layer tension; high laser damage thresholds; coating of bonded assemblies possible by using low coating temperatures

|

|

Spectral range

|

- Standard 190 to 2000 nm; other wavelengths on request

|

|

Substrate material

|

- Optical glasses, flat glasses, colour glasses, fused silica, sapphire, glass ceramics, ceramics, silicate glasses, semi-conductor materials, special materials on request

|

|

Dimensions

|

- Client-specific optical components (plano plates, prisms, lenses…) and bonded groups

- Anti-reflective flat glasses on request with blanks as per client’s requirements

|

|

Metrology

|

|

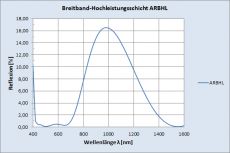

High-reflection coatings

Examples of coating curves

High-reflection coatings (specifications)

|

Application

|

- Reflection or deflection of light rays; the reflection of substrates is increased up to 99.99% through metallic and/or dielectric coatings

|

|

Types of coatings

|

Metallic high-reflection coatings

- Aluminium with protective layer (AL protected)

- Aluminium with dielectric enhancement layer (AL enhanced)

- Silver with protective layer (AG protected)

- Gold (AU bare)

- Gold with protective layer (AU protected)

Dielectric high-reflection coatings

- Laser-Line high-reflective coatings

- HR laser mirrors for one or several wavelengths

- HR laser mirrors with several additional functions

- Broadband mirrors with high reflection (e.g. cold light mirror)

- Dichroic mirrors

- Semi-transparent mirrorsR-Laserschicht

Special reflection coatings as per client’s requirements.

|

|

Our competences

|

- Hard, scratch-resistant layers; high laser damage thresholds; coating of bonded assemblies possible by using low coating temperatures

|

|

Spectral range

|

- metallic mirrors 190 to 12.000 nm; dielectric mirrors 240 to 2.000 nm

|

|

Angle of incidence

|

- 0°-60° s-polarization and p-polarization

|

|

Substrate material

|

- Optical glasses, flat glasses, Borosilicate glasses, filter glasses, fused silica, glass ceramics, ceramics, special materials on request

|

|

Dimensions

|

- Client-specific optical components and bonded groups

- Front surface mirrors with Al coating on flat glasses on request; blanks client’s requirements

|

|

Metrology

|

|

Filter coatings

Examples of coating curves

Filter coatings (specifications)

|

Application

|

- For elimination of disturbing extraneous light in optical measurement systems; e.g. in the use of laser or LEDs

|

|

Coating types

|

- Short-pass filter

- Long-pass filter

- Variable bandpass filter

- Narrowband filter

- Dichroic colour and illumination filter

- Heat reflection filter

- Neutral density filter

- Special filters as per client’s requirements

|

|

Our competences

|

- Hard, scratch-resistant, thermally and mechanically stable coatings; high laser damage thresholds; for extreme environmental conditions; outer space compatible; saltwater resistant

|

|

Spectral range

|

- Standard 240 to 2.000 nm; other wavelengths on request

|

|

Substrate material

|

- Optical glasses, flat glasses, Borosilicate glasses, filter glasses, fused silica, special materials on request

|

|

Dimensions

|

- Client-specific optical components; coated flat glasses on request; blanks as per client’s requirements

|

|

Metrology

|

|

Beamsplitter coatings

Examples of coatings curves

Beamsplitter coatings (specifications)

|

Application

|

- For separation of light rays, without changing the spectral range; for example, corresponding signals or images are generated at different locations through beam splitters

|

|

Coating types

|

- Dichroic and metallic beamsplitters

- Polarizing and non-polarizing beamsplitters

- Bonded and non-bonded beamsplitters

- Beamsplitters for single wavelength or broadband

- Special beamsplitters as per client’s requirements

|

|

Our competences

|

- Hard, scratch-resistant, thermally and mechanically stable coatings; high laser damage thresholds; for extreme environmental conditions; outer space compatible; saltwater resistant

|

|

Spectral range

|

- 240 to 2.000 nm; other wavelengths on request

|

|

Substrate material

|

- Optical glasses, flat glasses, Borosilicate glasses, fuses silica, special materials on request

|

|

Dimensions

|

- Beamsplitter plates or beamsplitter cubes as per client‘s specification; beamsplitter plates with split ratios of R/T = 30/70, 50/50, 70/30 in VIS und NIR; see Products on stock

|

|

Metrology

|

|

Transparent and electricoconductive coatings (ITO) (specifications)

Transparent and electricoconductive coatings (ITO) (specifications)

|

Application

|

- For heating of surfaces (e.g. for fog susceptible optical systems); adjustable thermal resistance (Ω/q) to avoid static charges

- transparent electrodes

|

|

Coating types

|

- ITO (Indium Tin Oxide) in defined layer thickness

|

|

Our competences

|

- In visual range highly transparent

- Hard, scratch-resistant, thermally and mechanically resistant

- Can also be supplied with additional anti-reflective properties

|

|

Substrate material

|

- Optical glasses, flat glasses, Borosilicate glasses, filter glasses, fused silica, special materials on request

|

|

Dimensions

|

- Client-specific optical components; coated flat glasses on request; blanks client’s requirements

|

|

Metrology

|

|

Gold solderable coatings (specifications)

|

Application

|

- For soldering micro-optics and small optics; replaces the conventional bonding or adhesive technology

|

|

Coating type

|

|

|

Our competences

|

- Special development for laser-specific joints

|

|

Substrate material

|

- Optical glasses, flat glasses, filter glasses, Borosilicate glasses, fused silica, special materials on request

|

|

Dimensions

|

- Client-specific optical components

|

|

Metrology

|

|

Chromium coatings / Microstructures in chromium coatings

Chrom-Schichten (Spezifikationen)

|

Application

|

- For microstructures and other applications

|

|

Coating types

|

- High-reflective coating HRC (normal chromium coatings)

- Low-reflective coating LRC (black chromium coatings)

- Combination of layers (chrome/chrome oxide)

- Narrow and broadband coatings

- Special layers as per client’s requirements

|

|

Our competences

|

- Different coating thicknesses, customized coating combinations and optical densities as per client’s requirements

|

|

Substrate material

|

- Optical glasses, flat glasses, Borosilicate glasses, filter glasses, fused silica, special materials on request

|

|

Dimensions

|

- Client-specific optical components; coated flat glasses on request; blanks client’s requirements

|

|

Metrology

|

|

Mikrostrukturen in Chrom-Schichten (Spezifikationen)

|

Application

|

- Microstructures in chromium coatings for measurement technology, image processing, medical applications, laser technology and other applications

|

|

Designs

|

- Micro-lithographic structures in metallic layers (Cr/Cr2O3) on glass and other carrier materials

- Through photo-lithographic multiple methods structured components can be produced very economically in high volumes.

|

|

Our competences

|

- Sophisticated, finest structures and precision divisions; including total solutions: optical components, coatings and micro-lithographic structures

|

|

Substrate material

|

- Optical glasses, flat glasses, Borosilicate glasses, filter glasses, fused silica, special materials on request

|

|

Dimensions

|

- Client-specific optical components; cut according to client’s requirements

|

|

Metrology

|

|